We’ve seen a dramatic shift in the automotive industry in the last few years: vehicles are becoming more fuel-efficient, logistics are planned without waste, and electric commercial vehicles are on the rise.

But this focus on sustainability has extended to workshops, too: with new eco-friendly features and energy-efficient designs in the workshop equipment we use.

Here’s what that means for eco-conscious workshops — and the business benefits it can bring:

Low Energy, Low Costs

Heavy-duty equipment comes with heavy-duty energy needs. Manufacturers know this, and they’re constantly improving their designs to minimise the energy their equipment uses — without sacrificing the power and features a workshop needs.

With an upgrade to a modern piece of kit, you can save energy with:

- Compressors using IE3 or IE4 motors — designed especially for lower energy consumption

- LED lighting in your inspection pits — using a fraction of the energy, and lasting much longer

- Induction heaters in place of torches — heating parts directly to save energy

That’s all great news for workshops going green. But it can also have a huge impact on your bottom line:

Even the smallest improvement in energy efficiency can add up over several pieces of equipment — especially in areas like LED lighting, where they’re drawing power all day long.

So as well reducing your impact on the environment, you’re reducing the utility bills in your premises — lowering your overhead expenses, and improving your profits as a welcome bonus.

Less Waste is Good for Everyone

Between lubricants, oil, and antifreeze, a typical vehicle workshop is rife with potentially harmful liquids.

When these chemicals aren’t managed properly — especially in the case of spills and disposal — they can escape into the environment and cause serious harm.

To prevent this risk, manufacturers are constantly developing new tools for fluid and oil management: making it easier and safer to deliver, collect, and dispose of those chemicals.

That means thinking about:

- Electric pumps — to deliver oil and diesel accurately, without spillage or waste

- Waste drainers — to safely collect excess oil and fluids, so it can be disposed of properly

Just like energy-efficient bulbs and compressors, a dedicated piece of waste management kit is doing double-duty:

You’re protecting the environment from the escape of harmful chemicals. But you’re also reducing the oils and fluids that your business loses. You’re minimising the cost of buying in materials, and lowering your expenses as a result.

Long-life Tools for a Better Investment

From a business perspective, every workshop wants high-quality tools that last as long as possible.

But there’s a bonus to choosing the most durable and long-lasting equipment: it reduces your overall impact on the environment.

There’s a lot that goes into the production of each piece of kit — from materials and production emissions to transport and delivery. And when we’re talking about big-ticket items (like vehicle lifts and inspection pits), your effect on the environment becomes even bigger.

So when you choose the highest-quality equipment — with a focus on durability and long-life construction — you’re extending the lifespan of the equipment you invest in. You’re reducing the frequency of repairs and outright replacement, and minimising the impact each purchase has on the environment.

In practice, that means looking for things like:

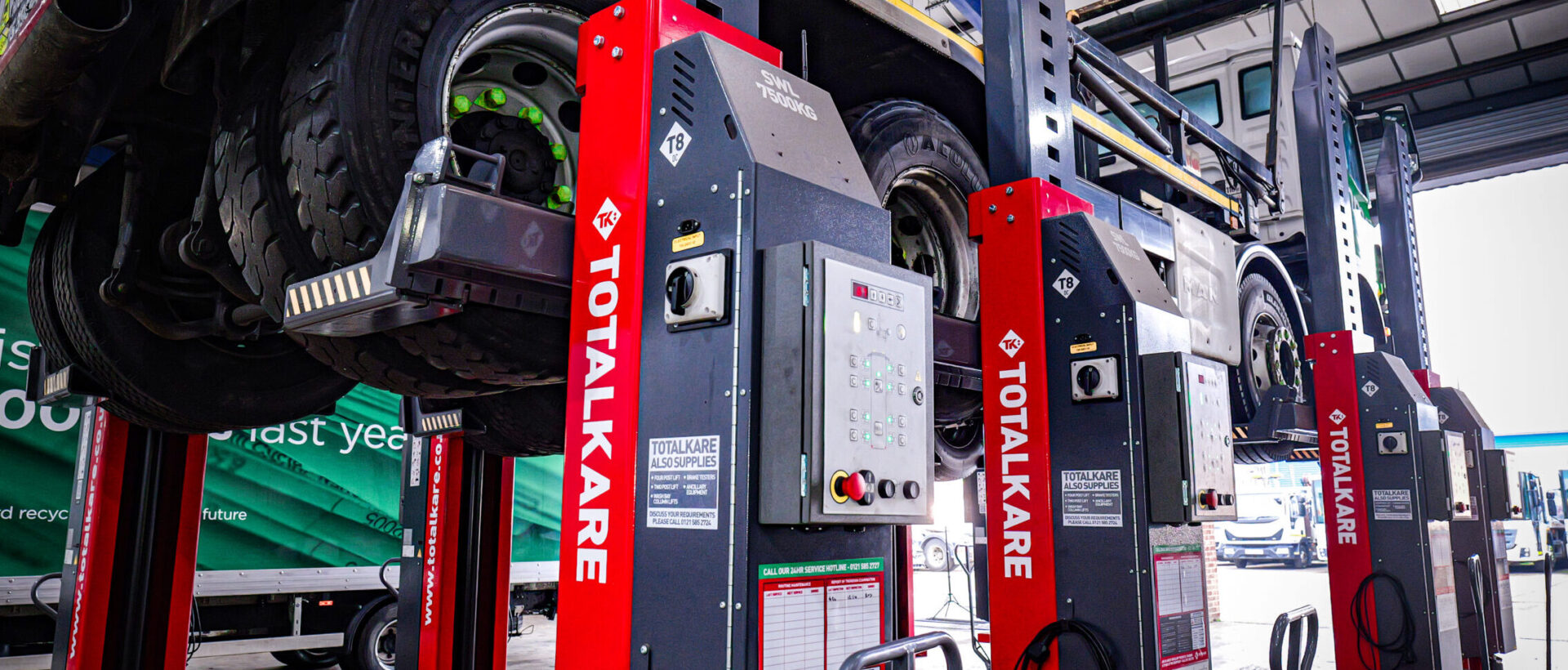

- Special protective coatings — like the galvanisation options on our vehicle lifts

- Durable components and solid engineering

- Equipment designed to last in rugged environments — like an outdoor Wash Bay Column Lift

- Equipment with options for expert service contracts — to extend its overall lifespan.

While these high-quality options usually come at a higher price, it’s an investment that usually pays off in the long run. With equipment that can last for decades, you’re reducing the overall spend of replacing it after a year or two — giving you an improved ROI, despite a higher initial cost.

This article was originally published by Totalkare.