There’s no such thing as the perfect piece of kit — no matter how much you spend, or how well you maintain it.

With the everyday rigours of heavy use in the shop (or a simple mistake from a technician), even the best possible equipment can see moments of downtime.

And from our experience working with all kinds of workshops:

It never happens at a good time, or when you expect it.

So as well as doing everything you can to prevent it, you need a contingency plan for equipment failure that can help get your kit up and running as fast as possible.

Here’s how to reduce equipment downtime, and the steps you can take now to be ready for the worst:

Cross-train your staff

Some workshops use equipment with only a few people who can troubleshoot it. Most of the time, it’s smooth sailing — until the equipment fails when that person isn’t around.

In most cases, a quick diagnosis is the best way to reduce downtime. So the most prepared workshops are the one who teach the basics to as many people as they can.

They don’t need advanced knowledge or the training of a qualified engineer. But they do need a basic understanding of the low-level diagnostics that can help them pinpoint the problem and try a few easy fixes.

That could be as simple as training more staff how to:

- Check fuses, connections, and power cables

- Locate safety mechanisms and sensors (and check them)

- Understand the most common error codes and fault messages

- Carry out a system reset

The more people you have trained in these low-level checks and fixes, the sooner you can diagnose the problem (or eliminate potential causes).

Ideally, you’ll have this important information ready in an accessible ‘playbook’ — a checklist of steps to take in the event of equipment failure, including any third-party services they should contact.

Arrange remote support

While emergency callouts are a huge help, they can’t arrive instantly. But there are ways to get expert advice in the first few moments. In some cases, you might get an instant fix to the problem — which means almost no downtime for your equipment at all.

It’s especially helpful after your on-site teams have run through their checklist. If they’ve diagnosed the problem (or ruled out alternatives), they can pass that information along to give the remote technician a head start.

Remote support could look like:

- Remote diagnostics through software and sensors

- Remote control to adjust settings

- Guided repair through a video call.

Or in some cases (like our afterkare service contract), you’ll get a 24-hour service hotline. You’ll have expert advice and support as soon as a problem arises — no matter the time of day or night.

Network with local businesses

Most businesses carry spares and backups of certain types of equipment — and most businesses are just as vulnerable to downtime as yours.

So if you have a good relationship with other nearby businesses, you can build a co-operative arrangement to share extra equipment when either side gets into trouble.

This is especially useful for general equipment that crosses over between different industries — not just vehicle workshops. That could mean things like:

For equipment designed specifically for commercial vehicles, you won’t have much luck trying to share equipment with your competitors.

But there’s nothing to stop you co-operating with local garages that service passenger cars and non-commercial vehicles. If you ignore the heavy-duty equipment, there can be a lot of overlap, such as:

Get a service contract in place

If you’re worried about equipment downtime, a service contract from a reputable supplier is one of the easiest ways to have a contingency plan always at the ready.

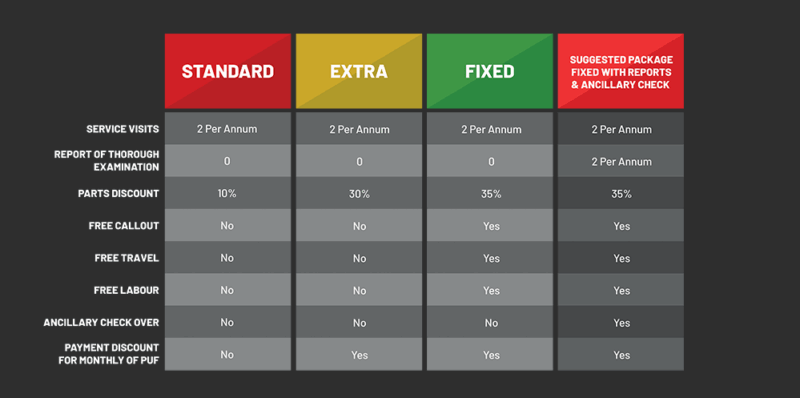

As well as the usual service visits and preventative maintenance (which already help you reduce your downtime), you’ll also have specialist engineers available for callouts in the case of equipment failure.

Depending on the supplier and the type of contract, those engineer callouts could be included for free. And in some cases, you’ll get a discount on the spare parts you need for a repair.

Here’s how that looks for the different packages in our Afterkare service contract:

With the ongoing support of a service contract behind you, you’ll have a responsive team ready to guide, support, visit, and repair — so you can minimise your equipment downtime and get your workshop back on track.

You can see exactly what you get with an afterkare service contract — or chat with a workshop expert to talk through your options.

This article was originally published by Totalkare.