Earlier this week, I had the fortune of visiting Wrightbus’ bus manufacturing factory in Ballymena, Northern Ireland. As Britain’s leading bus manufacturer, Wrightbus is set to produce over 1,200 buses from this site in 2025 alone.

Seeing the operation firsthand, it was clear that ambition and innovation are engineered into every vehicle, helping to shape the future of sustainable transport.

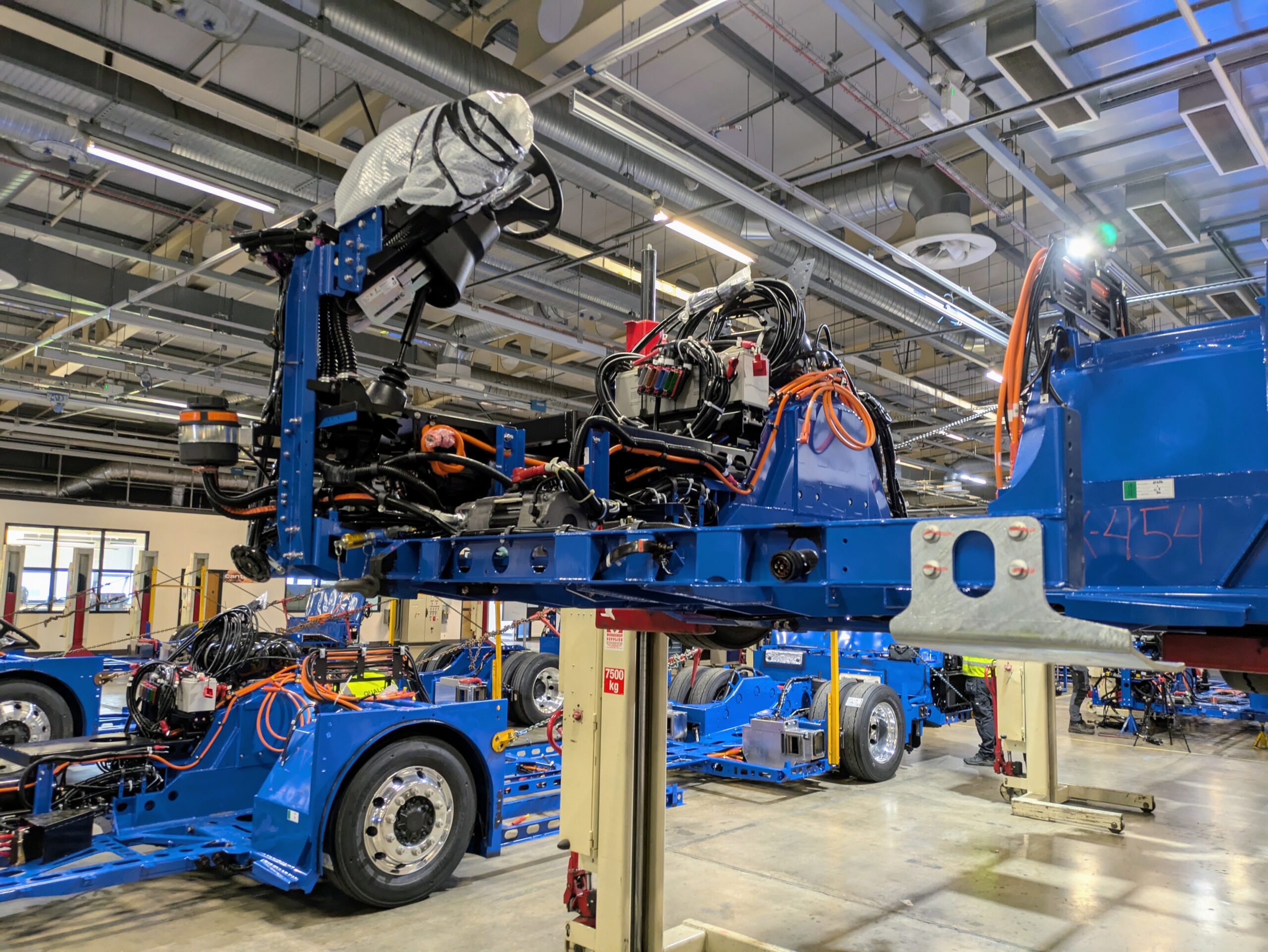

Chassis Assembly

Our tour began in the chassis factory, and it was immediately evident how clean, organised, precise and efficient the factory operations were.

Production runs around the clock, with night and day shifts rotating seamlessly. Each chassis moves methodically through designated zones, where skilled workers complete each specialised task.

Once assembled, every chassis goes through a rigorous quality inspection, which takes between 5 and 7 hours.

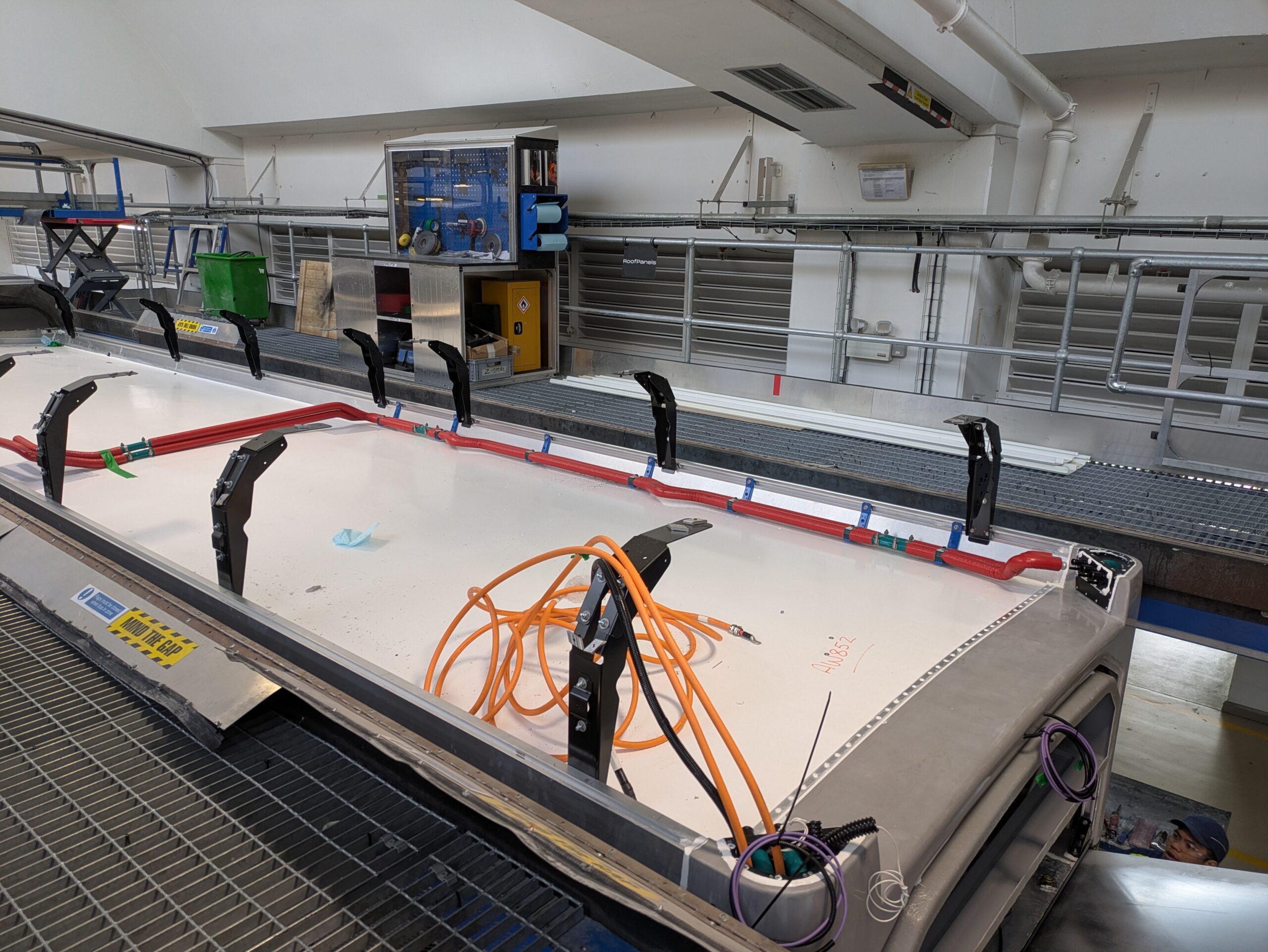

Body Shop

Alongside chassis production, Wrightbus also has a dedicated shop for producing aluminium-structured bus bodies. This factory operates Monday to Thursday, producing 32 completed bus bodies each week.

Again, each bus in the factory moves through a production lane, while separate components, such as staircases, are made in a dedicated area before being fitted alongside interior seating and flooring.

To complete this skilled work, Wrightbus directly employs over 2,200 people, alongside supporting thousands more jobs in the supply chain. This workforce includes a growing number of apprenticies.

Finishing Factory

Our tour concluded in the finishing factory, where buses are personalised and readied for the end customer.

Here, vehicles are painted in customer liveries and fitted with final components, presenting rows of completed buses ready to roll out and serve communities across the UK and beyond.

At Ballymena, the scale and precision of Wrightbus’ operation highlight the company’s position at the forefront of UK bus manufacturing. Standing on the factory floor, it was impossible not to feel the momentum: innovation, ambition, and pride built into every vehicle.

Read more about Wrightbus’ long-term plans here.