A Leading Supplier of Lightweight Systems for Road and Rail

Innovations and intelligent systems are the future of public transportation and individual mobility. Some of these are already in use today and we truly understand, support and expand these ideas here at 3A Composites Mobility.

With the experience, superior engineering, specialized manufacturing methods and a complete dedication to the perfection of our products, we have been a trusted manufacturer of lightweight composite elements for various purpose vehicles for decades. But 3A Composites Mobility’s goal is to go far beyond, channeling public transport development ideas into ground-breaking technologies that will set the company ahead of competitors in the market of components for mobile applications.

Our lightweight products are already helping today with carbon footprint reduction by efficient energy consumption, which is much appreciated by our clients. As for now, our portfolio focuses on integrated systems like train front ends, floors and roof systems, vehicle side walls and other elements serving in many different vehicles around the globe.

The company is a long-term business partner and manufactures its products for major rail and road vehicle brands. With the world rapidly evolving and people agglomerating in mega-city structures, we believe efficient mobility is one important element of our future. 3A Composites Mobility is here to offer supporting solutions for the necessary vehicles.

We bring in creative ideas, high technologies and strong values like concern for environmental protection to the business, so our customers and the operators using their products are able to benefit from them too. Your company is no exception: Together we are stronger – let’s make the world better.

Lightweight Composites for Road Vehicles

Innovative bus manufacturers have two essential goals: to achieve modular production and to maximize weight reduction. 3A Composites Mobility offers ideal ways of achieving both aims: sandwich-panel elements for roofs, floors and raised floors. The advantages are self-evident: sandwich panels are lightweight, modular and durable.

3A Composites Mobility has developed attachment concepts for sandwich-panel and composite applications, for use in hybrid or aluminum constructions. These combinations open up the potential for a weight reduction of more than 100 kilograms per component. The 3A Composites Mobility concept for these system components and their interfaces, as used in bodywork and interiors, takes into account the requirements of the bus manufacturer, especially with regard to service life, design and production.

Modular

Sandwich-panel applications are especially suitable for modular and efficient bus production. Heavy loads, such as air-conditioning units and interior fittings, can be installed in preassembled modules. High weight-specific rigidity and continuous, uniform supporting structures make more rational manufacturing processes possible. This means fewer construction variants in both series development and production.

The advantages are self-evident:

- Shorter assembly times and lower total costs of production.

- Short, efficient assembly lines and smaller production areas.

- Attractive workplaces: optimized ergonomics in final assembly; no overhead assembly.

- Sandwich components with low total weight and higher rigidity simplify construction inside and out.

- High quality in sandwich-panel production and during structural work on the bus.

- Less adjustment work due to tolerant connection technology, high rigidity and standardized components.

- The uniformity of sandwich-panel assemblies maximizes flexibility and improves incorporation of customer requirements, even during later construction phases.

Partnership

The demands made on the system solutions require close cooperation with our customers. This embraces both initial development and development for full-scale production. Cooperative and innovative development work with suppliers of materials is part of this. 3A Composites Mobility enters into strategic partnerships in order to offer our customers optimal system solutions.

Fiber-Reinforced Composites

Fiber-reinforced construction components that use glass fiber reinforcements (GRP) or carbon fiber reinforcements (CFRP) offer solutions to design and rigidity requirements. 3A Composites Mobility uses its proven competency in production processes for the manufacture of resin transfer moulding (RTM) and vacuum resin infusion (VAC) components. 3A Composites Mobility produces large, small and hollow components, using sandwich-panel construction technology.

3A Composites Mobility has achieved excellent results with a production application of rollover bars for tour buses. Development projects for passenger car floors have proved equally successful. Devised for the bus industry, these innovative lightweight solutions are shaping the culture of utility vehicle manufacturing, too.

Widely Recognized Global Brands

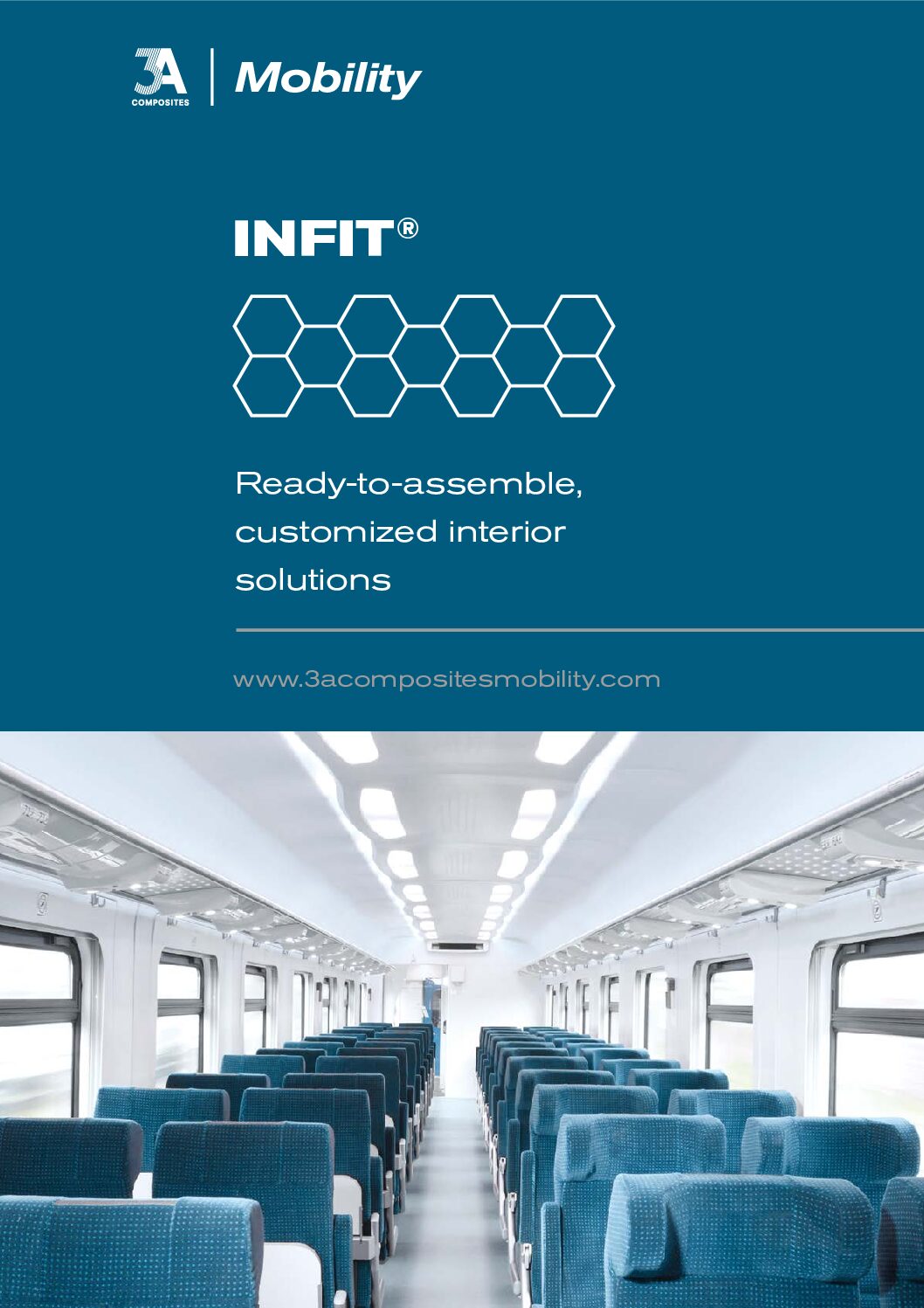

3A Composites Mobility provided just what manufacturers were looking for when it pioneered the introduction of sandwich technology. The trend towards lightweight construction and cost optimization is gaining popularity among rail vehicle manufacturers. INNOCAB® front cabins, INFIT® interior components, COMFLOOR® floors and XBODY® sandwich-panel components are acclaimed solutions in this regard.