Sealing Solutions for the Automotive Industry

Mobility is changing and Freudenberg Sealing Technologies’ Automotive segment is moving in stride with it. As an already established market leader in the industry technology, quality and service segments, our expertise now positions us to produce innovative, and cutting-edge products. These new products, ranging from fuel cell components to EMI shielding plastics, will help shape the future adoption of developing propulsion systems, ranging from passenger vehicles to trucks to buses. Whether it’s fuel cell, battery electric, hybrid or conventional combustion technology, join all of the major automobile and commercial vehicle manufacturers worldwide that are already innovating together with us!

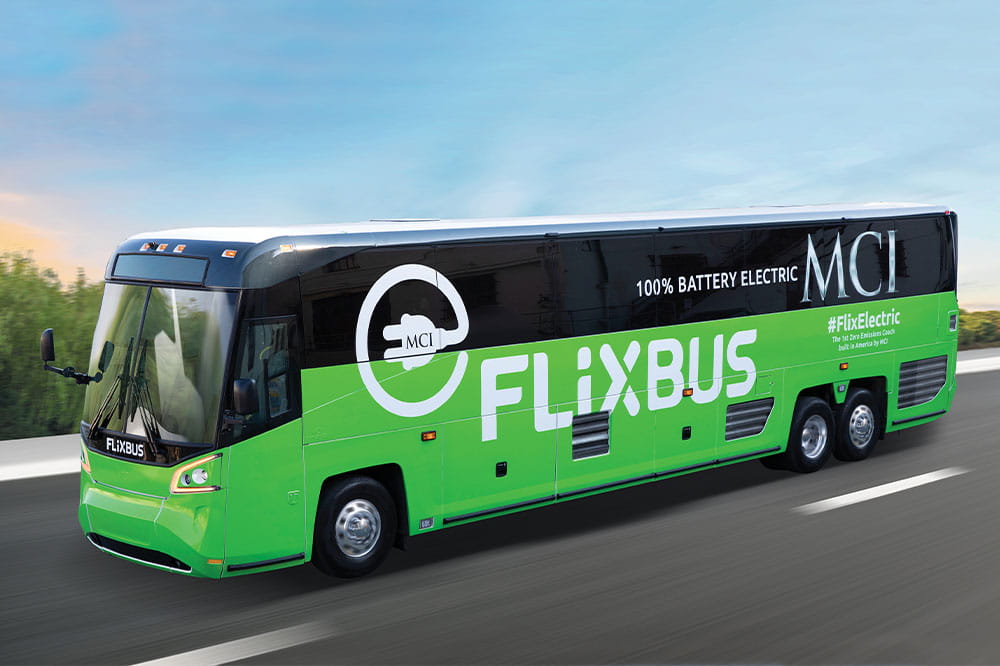

Bus & Truck

We are a supplier to all the major vehicle manufacturers worldwide, whether our contribution is an individual, standard engine seal or a component system developed to meet a particular requirement. You always receive parts of the highest quality as well as comprehensive expertise. Along with longevity, efficiency and TCO, the relevant issues for commercial vehicles are the varying requirements across regions – especially when compared to passenger cars – and exhaust gas after-treatment to reduce nitrogen oxides (SCR). Furthermore, our customers have direct access to a wide-ranging network of global research and development facilities, an extensive assortment of materials, technical experts and manufacturing specialists. In cooperation with our OEM customers, the Freudenberg Sealing Technologies Automotive team is ready to assist you with the implementation – even when your requirements are unique.

Battery

Advanced lithium batteries are used for EVs, P-HEVs, but also for 48 V mild hybrid vehicles. Besides this, they are also required for future fuel cell vehicles. Battery technology for mobility is changing rapidly. FST is in turn fine-tuning its portfolio to offer its customers top of the line solutions in gasket sealing, cell fixation, thermally conductive gap fillers and materials, pressure regulating elements, connectors, cooling tubes, and full integration of sensors into connectors. In addition, we are also working on lithium cell components such as our in-cell gap fillers.

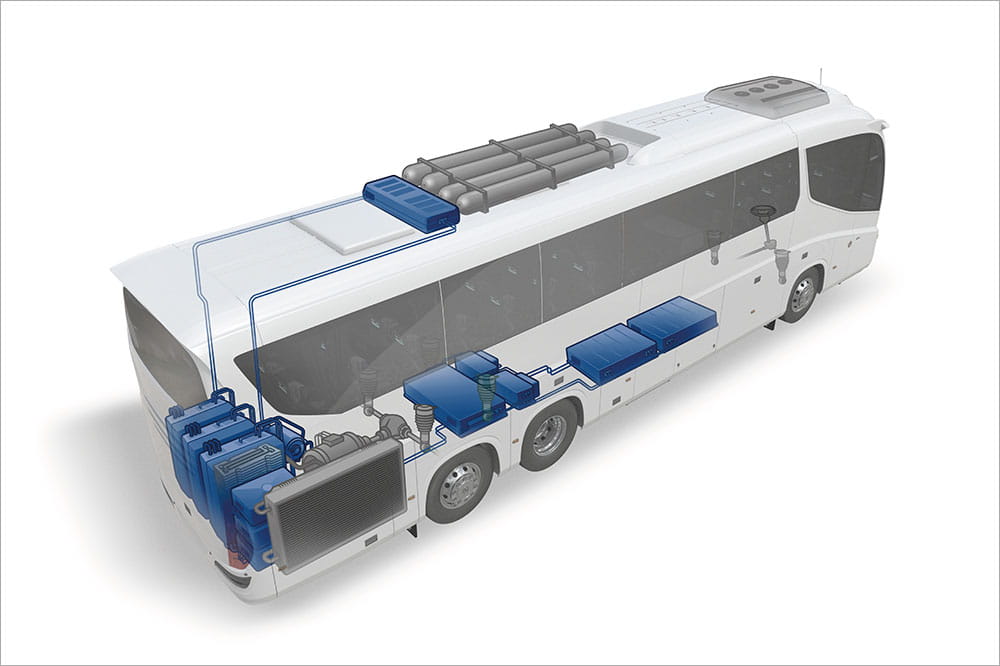

Fuel Cell

Low hydrogen permeation materials, water, safety, tolerance compensation in the stack, vertical integration (different Freudenberg components). Low hydrogen permeation materials, water, safety, tolerance compensation in the stack, vertical integration (different Freudenberg components) are all different forms of competencies and value we bring to our customers. We work as a partner to help develop customized solutions together with our customers.

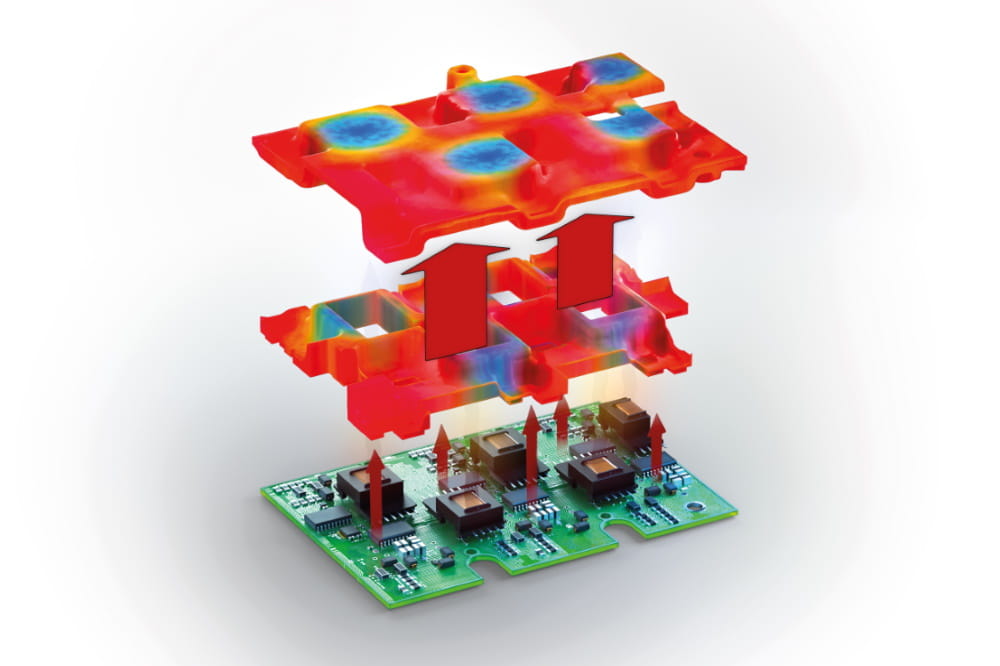

E-Power Train and Power Electronics

The electrification of mobility is driving change in the powertrain and increasing the use of power electronics. FST is poised to provide products that foster the increase of greater power densities through our thermal management materials and electro management interference (EMI) solutions. And as expectations of reliability continue to extend, so do our solutions to support it. Whether it is products that are electrically grounding or regulate a desired pressure in the system, FST has it.

Seals for Engines

Hybrid systems and e-drives are all well and good, but for the time being, powerful, low-emission and fuel-efficient combustion engines continue to set the pace in the automotive field. Friction-minimized engine seals point the way forward for conventional drive technology. FST’s Low Emission Sealing Solutions (LESS) help to optimize combustion, reduce consumption and CO2 emissions and thus ensure our future mobility while simultaneously working to reduce the impact on our environment. They meet the automotive manufacturers’ requirements; the drivers’ wishes and the legislative provisions in equal measure.

Fuel – Top Quality Alternatives

Fuel is the blood in an automobile’s veins and Freudenberg Sealing Technologies accompanies it on its path from the gas cap to the injection nozzle, irrespective of whether it is gas, biodiesel, flex-fuel, CNG or LPG that makes the automobile’s heart beat: Freudenberg Sealing Technologies offers a wide range of materials and sealing solutions that are reliably resistant against all types of fuel.

Seals for Transmission – Driving Innovation

With its seals for manual and automatic transmission systems, FST has been leading the field for many decades. On its way to ensuring our future mobility, the sealing specialist has used its friction-minimized and low-emission transmission seals to shift up a gear. Whether 4-step hybrid, 7-step double-clutch transmission systems or innovative seals for 8/9-step automatic transmission systems, Freudenberg Sealing Technologies drives innovation in transmission technology.

Drivelines – The Power Train: Driven by Durability

Seals from Freudenberg Sealing Technologies also provide the power train with innovative solutions that stand out due to perfect quality and excellent economic efficiency. Modern sealing technology in the power train makes it possible to minimize noise and vibrations, thus increasing the durability of the entire vehicle. Power train seals must be reliable, robust and durable. And that’s what Freudenberg Sealing Technologies’s Simmerrings®, cassette seals and joint bellows really are!

Seals for Steering & Suspension

When it comes to seals for steering systems, the sealing specialist focuses all of its activities on friction minimization, efficiency, a long service life and maximum installation safety. Whether steering bellows, end-stop dampers, Simmerrings® on the rack or in valves – steering seals from FST have been optimally designed for the specific characteristics of the individual component group and drive technology.

Yet there’s more to stability and safety than smooth and safe steering. The fine art of chassis design consists of harmonizing dynamics, stability and comfort. Potholes can be smoothened out and bumps are no longer an obstacle to safe driving and comfort. Friction-minimized chassis seals from Freudenberg Sealing Technologies make an important contribution to this: the lower the friction value in the bumper seal, the more precise the chassis design. This principle applies to passive and active chassis systems in equal measure.

Climate

Environmentally compatible coolants place new requirements on the material and design of seals in air conditioning systems. FST has developed a range of perfectly designed seals both for the HFO 1234yf coolant selected by the European automotive industry and the R744, its alternative.