Complete Cooling Systems

RAAL is a manufacturer of complete cooling systems and heat exchangers made of aluminium alloys and stainless steel, in brazed construction: radiators, oil coolers, air coolers, condensers and evaporators, designed for agricultural, construction, industrial equipment and automotive applications.

RAAL benefits from its 30 years experience in manufacturing complete cooling systems. Thousands of projects fulfilled stand for the various construction, dimensions and applications range and types. Such flexibility in achieving customer satisfaction is a testimony of RAAL commitment to reach high technological and research advancement. Our R&D team has the competence to elaborate programmes for the RAAL customers’ new products, so that it will differentiate them on the market, through innovation and performance.

RAAL is an integrated company and the design, sizing and simulation, testing and validation, prototype manufacturing, tool and die design and manufacturing, serial production activities are carried out “in house”.

This competitive advantage provides both a very short development and assimilation cycle in production of new products and short-term manufacturing and supply of the serially produced goods.

Values

- Flexibility – RAAL modular heat exchangers and cooling systems are adapted to the customers’ needs and are developed together with them. We provide custom cooling solutions for hundreds of applications; deliver tens of thousands of different products for small, medium and large series.

- Innovation – With a strong and creative R & D department, a well-equipped testing center, with patents for fins and new constructive / technological solutions, with 150 engineers who offer a range of 30-50 days to develop a new product and over 50 prototypes every month, we are always ready to deliver performance.

- Experience – The 30 years of experience in heat exchangers and teams specialized on domains and applications (R & D, heat exchangers design, tooling design, manufacturing, sales, logistics, and marketing), prove that each customer and each application are important for us.

- Partnership – The mutual trust, openness towards the latest technical solutions and customer approach are the core values of RAAL, that guarantee a long-term business relationship.

Manufacturing

- Aluminum alloys heat exchangers with 8 brazing lines, using the Nocolok technology

- Stainless steel heat exchangers with a vacuum furnace for stainless steel brazing

- Steel structures, as parts of the RAAL cooling systems

In two manufacturing sites in Romania: Bistrita on 12500 m2 and Prundu Birgaului on 32000 m2.

Engineering

R & D department, experienced and highly qualified, provides a very short development and assimilation cycle in production.

Design and simulation → Product design → Testing center → Prototype workshop → Tools and equipment

Logistics

RAAL is able to provide customized logistics services (transport, storage, distribution) according to customers’ needs and requests

RAAL has subsidiaries in Italy, Holland, Germany and The USA.

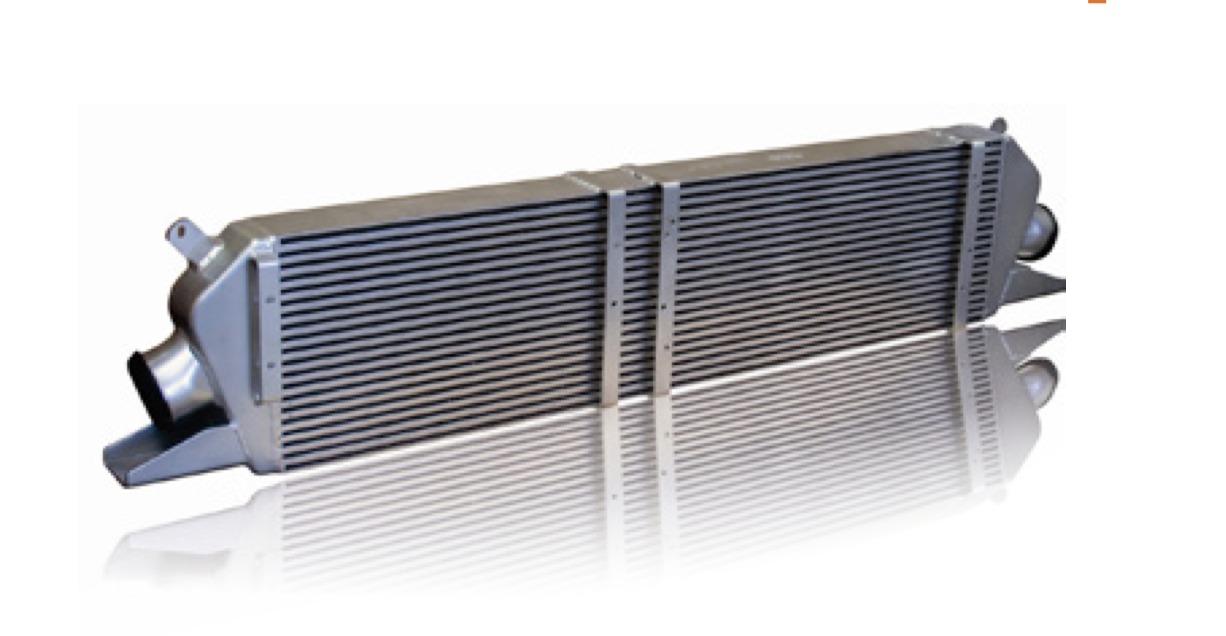

Commercial Vehicles

Features of the RAAL cooling systems for commercial vehicles:

- High cooling performance

- Compact construction

- Various available constructive solutions & configurations

- High resistance to dynamic thermal loads

- Low maintenance costs

- Reliability

RAAL manufactures cooling systems and individual heat exchangers for applications for commercial vehicles: radiators, oil coolers, air coolers, fuel coolers, heaters, condensers, EGR.