SABA Adhesives and Sealants

In just over 86 years, SABA has grown to become a global player in adhesives and sealants for specific B2B markets. Thanks to our focus on a select number of sectors, we offer unrivalled added value, with innovative products. Above all, we are a knowledge partner who helps raise customer processes and projects to a higher level.

Thanks to this targeted strategy, we are the leader in adhesives for foam bonding and chemically-resistant sealants. In Europe, we are also developing into a leading supplier of advanced adhesives and sealants for the transport industry.

Partnership with the customer is not just a mission, but something we continually invest in. With our knowledge of bonding and sealing, we continually raise the processes and projects of our customers to a higher level. We aim to achieve better, more sustainable results, lower total costs and a positive contribution for people and the environment. In other words, a partnership which makes things better for all of us and the world.

Smart Solutions for Touring Cars and Buses

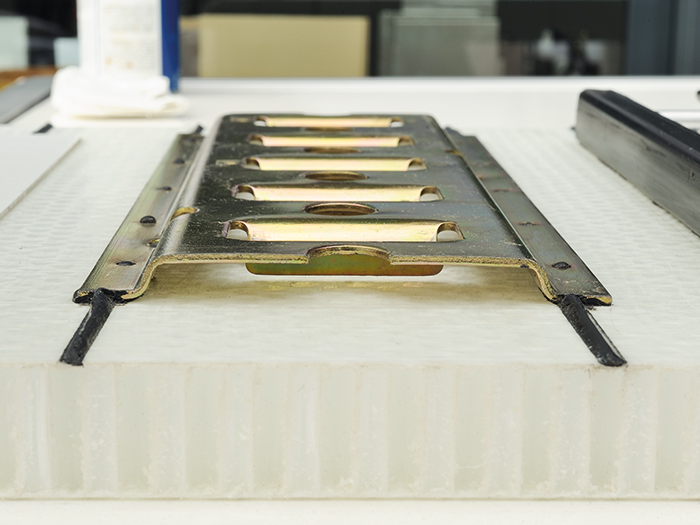

SABA adhesives and sealants for the production of touring cars and buses comply with the highest standards of elasticity, strength and durability. They also bond with many different materials, including glass fiber-reinforced polyester, powder coatings, composites, glass and metals and are suitable for:

- Sealing welds, roofing, floors, panels and interior parts

- Structural bonding of body parts, panels, roofing and floor elements

- Bonding and sealing windows made of mineral glass, polycarbonate or other plastics

- Coating floor elements

Adhesives and Sealants for a More Efficient Process

Our innovative R&D specialists and highly skilled technical representatives, often trained European Adhesive Specialists and Engineers, can share ideas on your production process. We specifically investigate ways to realize bonding and sealing faster and more securely for you. For example, we test our adhesives and sealants on the materials used in your production environment. We also advise on the optimal deployment of application equipment and machinery. In addition, our SABA application specialists are always ready to provide training and support for your production workers in adhesion and sealing processes, including in accordance with DIN 2304. In this way, we contribute towards a more efficient production process for touring cars, coaches and buses.

MS Polymer Technology

SABA has for years been a leader in the development and production of adhesives and sealants for bodywork assembly. With Sabatack®, we offer a unique product range, based on MS Polymer technology. Owing to its unique composition, Sabatack® has no labelling obligation and no hazard symbols. This is because the products contain no solvents, silicones or isocyanates. Isocyanates are harmful to humans and the environment. Breathing protection masks and special safety clothing must be worn while working with products containing isocyanates. Other benefits of SABA’s MS Polymer products include excellent bonding with metals and plastics, wet-on-wet overpaintable (no blistering) and the UV stability.