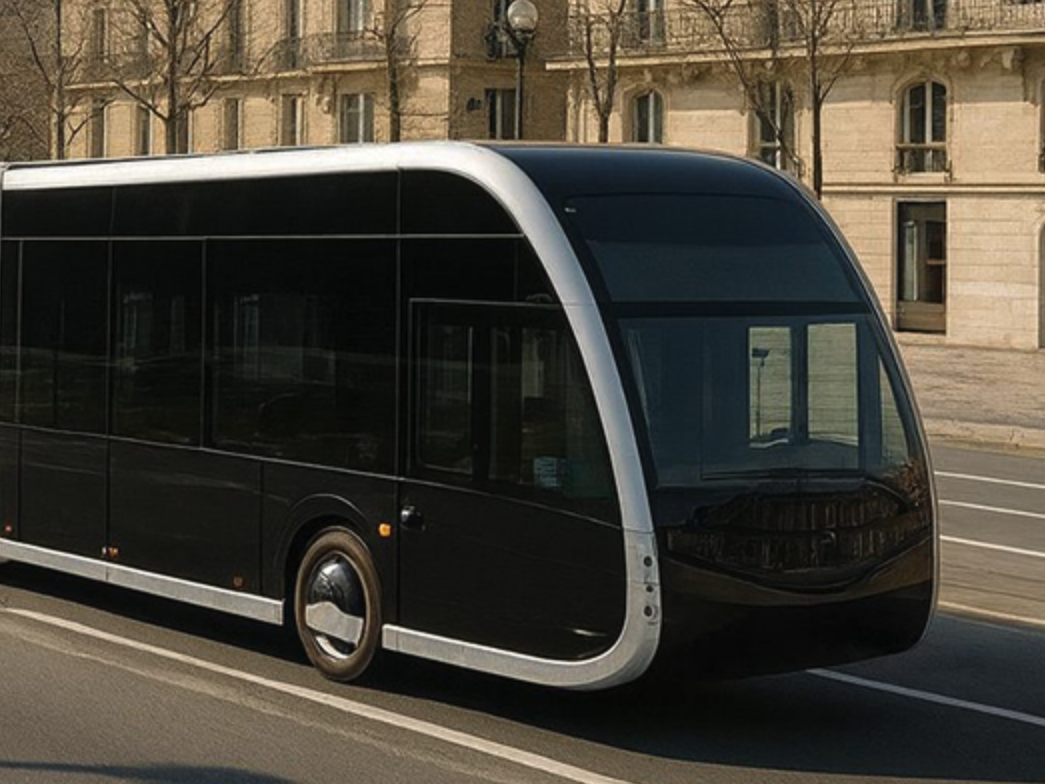

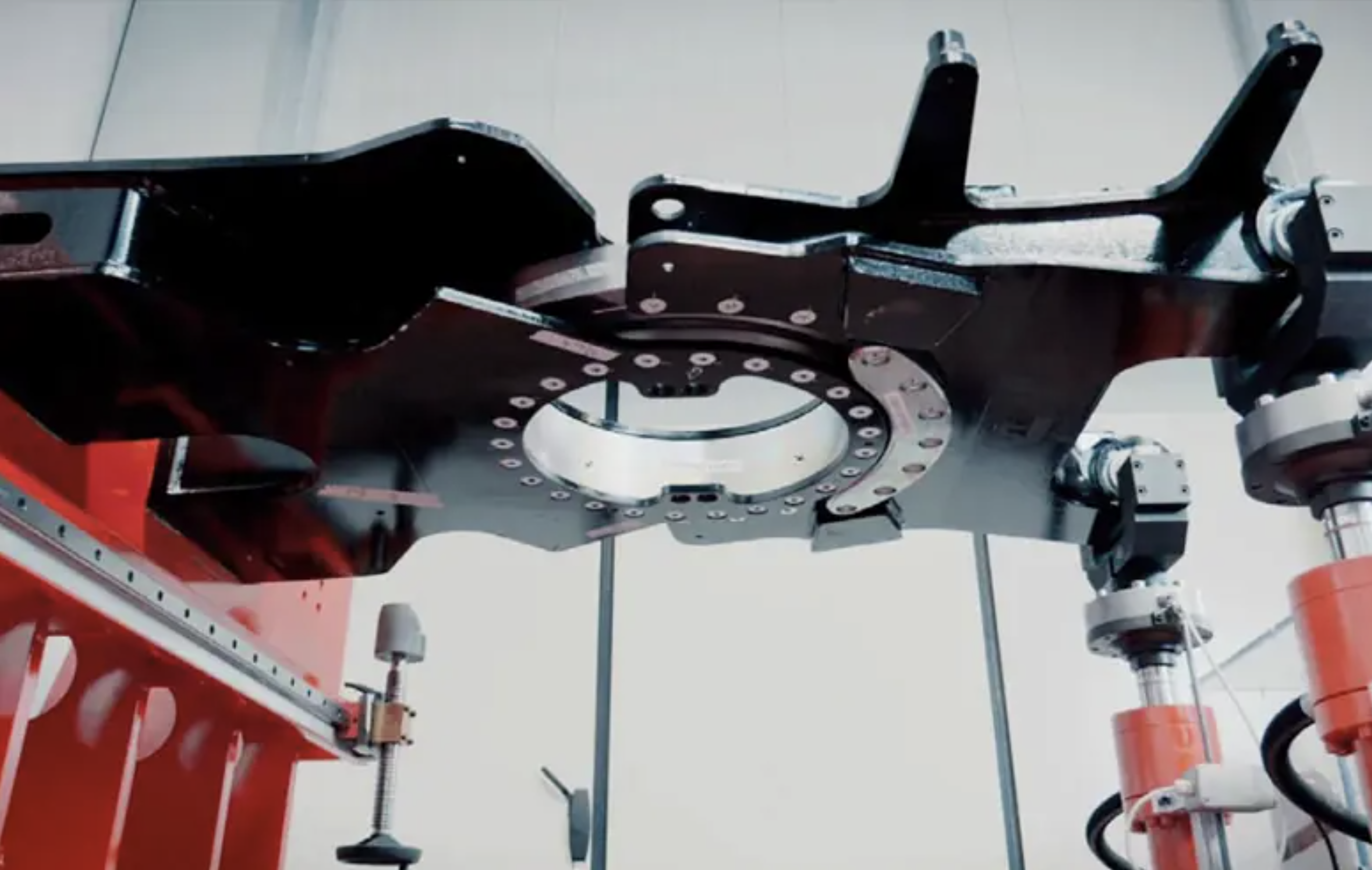

PEI Mobility, a company at the forefront of sustainable mobility, recently unveiled a new steel and carbon articulation that promises to revolutionise the environmentally friendly vehicle market.

The main innovation in this development is the use of SMC (Sheet Moulding Compound) technology in the design and manufacture of the articulation, opening up new frontiers in terms of efficiency and sustainability. The adoption of carbon fibre for these joints allows for a significant lightening of the joints. This weight reduction is not only an engineering victory, but brings with it a number of environmental and operational benefits:

The adoption of carbon fibre for these joints allows for a significant lightening of the joints. This weight reduction is not only an engineering victory, but brings with it a number of environmental and operational benefits:

- Lower fuel consumption: The reduced weight of the components contributes to lower energy consumption of the vehicles

- Greater Autonomy: With less weight, vehicles can cover greater distances on a single charge, improving operational efficiency by increasing range by up to 5%.

- Less Environmental Pollution: Reducing weight and energy consumption translates directly into lower harmful emissions, contributing to a cleaner environment.

SMC technology, which combines carbon-fibre reinforced polymer resins, makes it possible to create lightweight yet extremely strong components. This technological advancement is a significant step towards creating more sustainable vehicles, in line with global targets to reduce CO2 emissions and dependence on fossil fuels.

PEI Mobility continues to demonstrate its commitment to sustainable innovation, and this new steel and carbon joint is tangible proof of their ongoing efforts to improve efficiency and reduce the environmental impact of vehicles. With initiatives like this, the company not only contributes to a greener future, but also sets new standards in sustainable mobility.

This article was originally published by PEI Mobility.