As a global leader in composites, we develop composite solutions for a wide range of industries and applications, from wind energy to transportation to buildings.

With more than 60 years of experience collaborating with industry customers around the world, we work together with you to find the right composite solution for your applications.

The result is a high-performance solution that takes your products and applications further.

Composites for the Transportation Sector

Our specialists work closely with customers across a broad range of sectors, including transportation. Make stronger, lighter and more sustainable vehicles with internal and external composite profiles and stiffeners.

How Would You like to Use Composites?

Are you thinking about how you can take advantage of composites in your cars, buses, trucks, or trains? So are we. With a growing demand for safer, greener, and more sustainable vehicles, we can help you meet the challenge. We work with transport designers and system suppliers from across the globe to design, develop, and manufacture carbon fiber, fiberglass, and hybrid composite solutions for lighter, safer, and more energy–efficient vehicles.

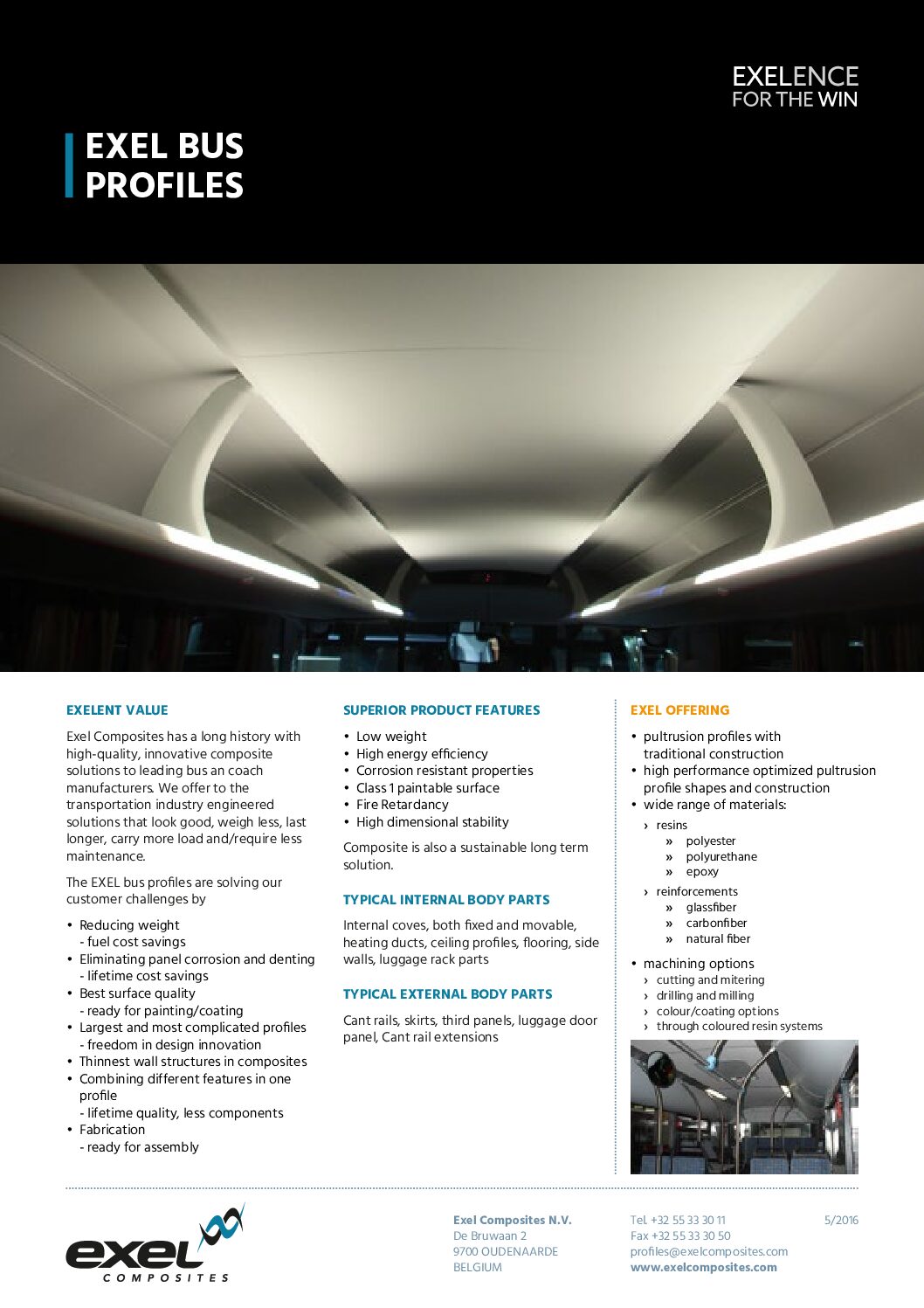

Bus & Coach Solutions

System suppliers and OEMs know that weight and material performance are key factors when designing the many functions and features of today’s buses and coaches and choose composites for these benefits. Composites such as fiberglass provide long life durability, reduce manufacturing complexity, and provide the desired surface finishes, for inside and outside the bus or coach.

Long-Life Durability

Fiberglass side panels easily resist the daily dings and dents public buses are subjected to, easily springing back into shape, and if needed, repairs are easily made in depot. With built-in corrosion resistance pollution or salty road conditions are no problem for composites, they don’t rust, and that means less maintenance over the bus’s lifecycle.

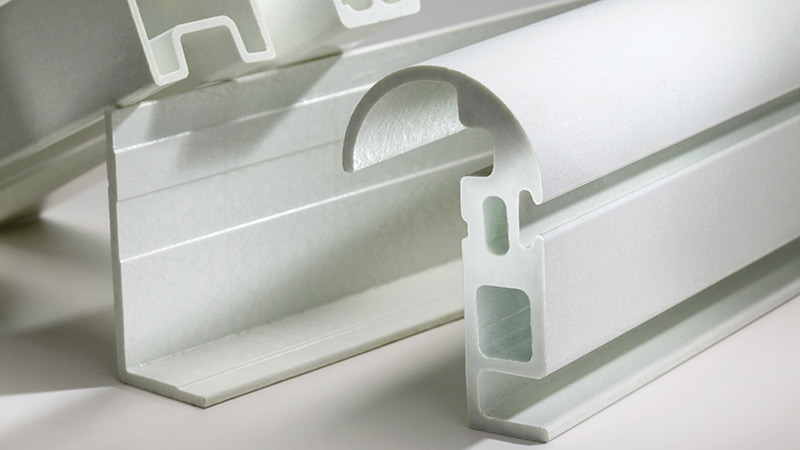

Help Reduce Design Complexity

We can design multiple functions into a single profile. For example, we can incorporate a hinge or cable channel into one complex profile. This reduces your overall part count and helps save manufacturing time.

Ready-To-Paint Surface Finishes

When designing your bus profile, we can incorporate veils into the manufacturing process which deliver a range of surface finishes, ready for painting without sanding or fillers.

Global Presence

As a global operator with over 60 years of composites experience, we’ve built up a wealth of local and international knowledge. We are available to discuss your needs and work with you to realize the full potential of composites. With a wide global sales and sales support network our focus is to truly understand your needs and discuss composite possibilities, and deliver quality products.