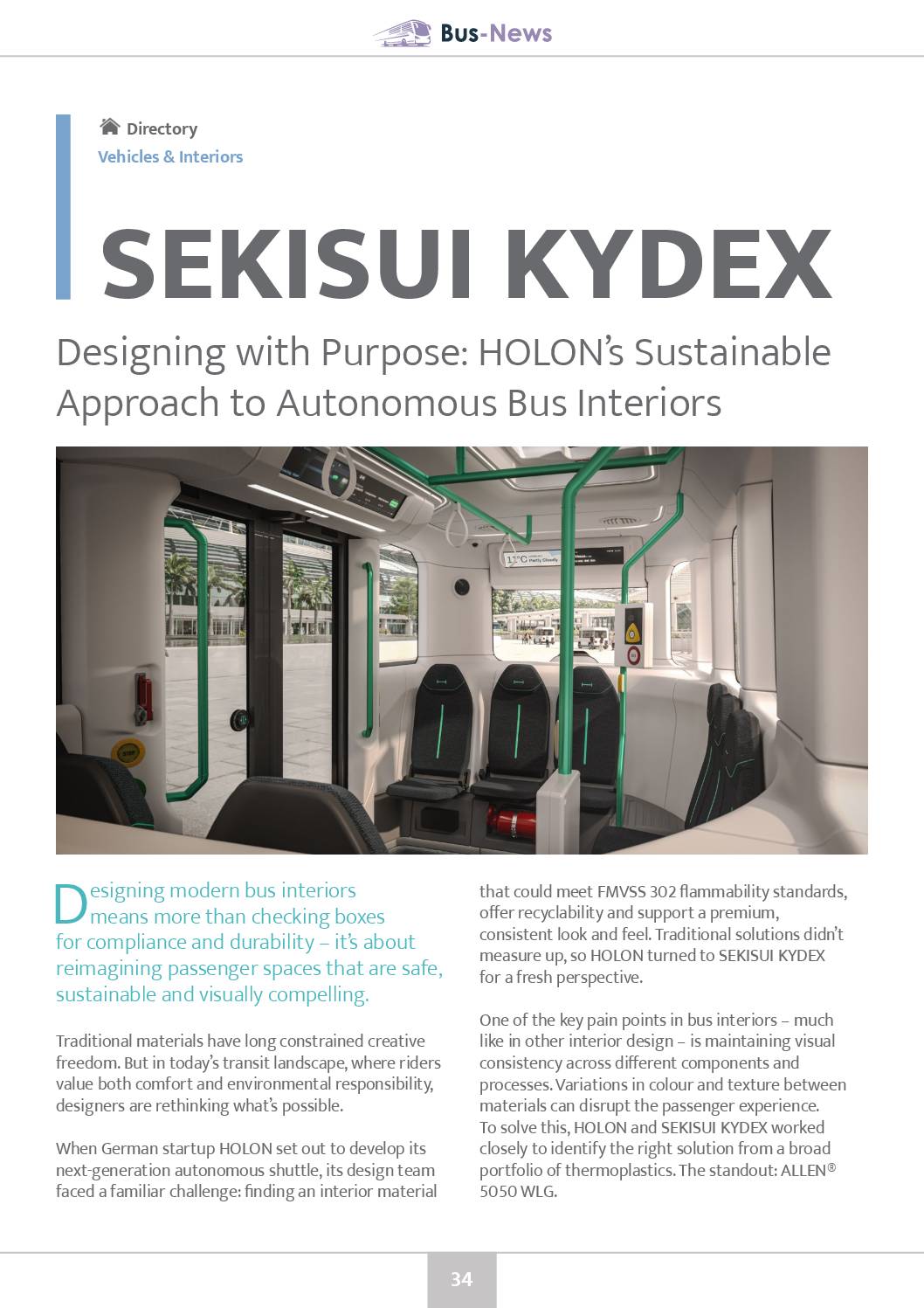

Thermoplastics for Bus Interiors

SEKISUI KYDEX innovates and manufactures KYDEX® Thermoplastics material solutions for the next generation of product design. SEKISUI Chemical’s corporate commitment to Speed, Service, and Superiority is realized through the KYDEX® Thermoplastic business model of manufacturing bespoke materials with short lead times in small quantities. This Quick Response Manufacturing (QRM) model at three manufacturing campuses expands beyond thermoplastic sheet. The KYDEX® portfolio also includes injection molding resins, proprietary Infused Imaging™ Technology, integral special effects, unique textures, and custom products and design.

The SEKISUI KYDEX appLab™ and designLab® innovation centers are collaborative spaces for clients and customers to bring the supply chain together for rapid prototyping and design development. These spaces are the bridge between engineering and art. More than 300 dedicated professionals in Pennsylvania and Michigan working with a global network of sales and distribution partners, are committed to delivering more than their customers can imagine.

The fully-compliant KYDEX® Thermoplastics portfolio meets all of the stringent requirements of industry certifications for passenger safety. With a refined degree of integral finish, colour, and design, KYDEX® Thermoplastics enhance the passenger experience in areas like seat backs, window shrouds, and monuments.

KYDEX® Thermoplastics offer ample design flexibility, while meeting the most stringent fire, smoke, heat release, and toxicity requirements, providing a fully-compliant portfolio to meet all of your rail application needs.

Products for Bus Applications

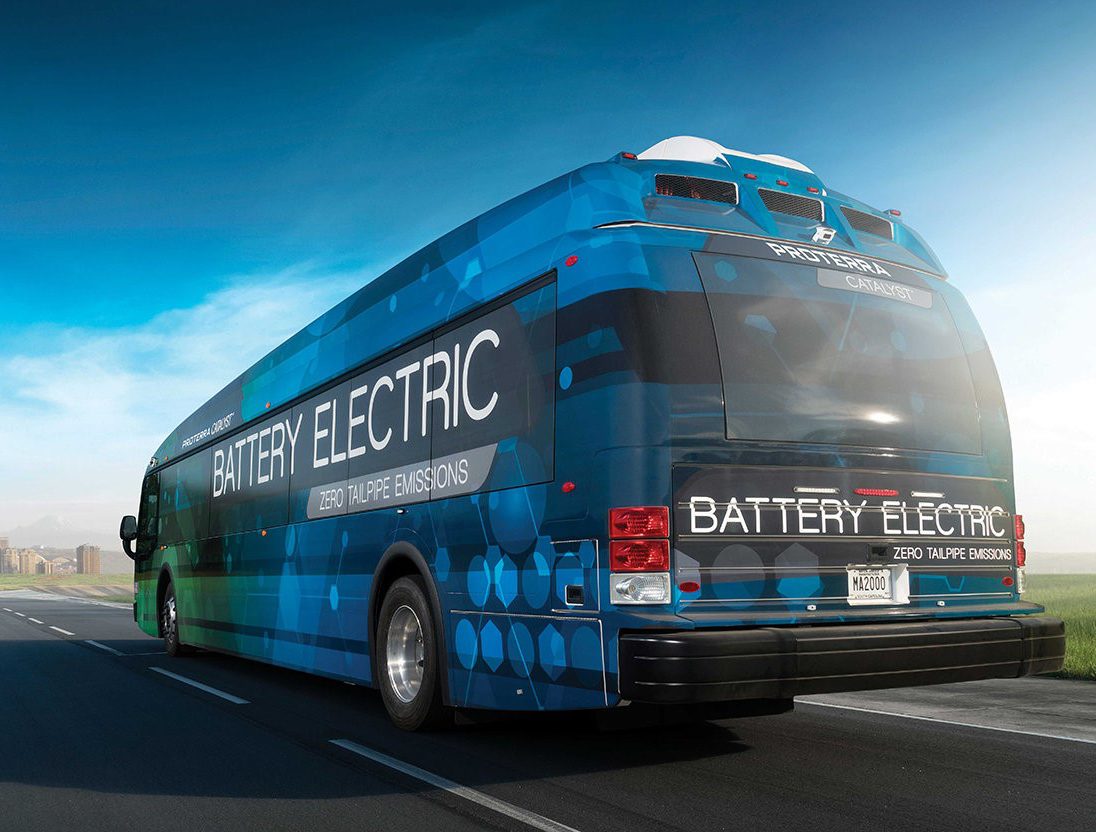

KYDEX® and ALLEN® Thermoplastics are designed to be aesthetically pleasing and meet the stringent requirements of external and internal bus applications.

KYDEX® 6200

FMVSS 302 & Docket 90 Compliant

A light weight and durable alternative to FRP offering unlimited design possibilities for shape, color, and embossed features including texture.

Features & Benefits:

- Customizable / Design Flexibility

- Excellent Chemical, Graffiti, and Stain Resistance

- Sustainable (Lightweight / Saving Energy)

- Forms to Deep Draws

ALLEN® ALEXTRA

FMVSS 302 & ASTM E 162 and 662 Compliant

Industry-leading durability for extreme weather conditions maintaining high impact properties with temperatures as low as -60°F. Raises the standard for high-gloss aesthetics.

Features & Benefits:

- For Exterior Applications

- Very High Gloss

- Customizable / Design Flexibility

- Sustainable (Recycling Buy-back Programs)

- Durable

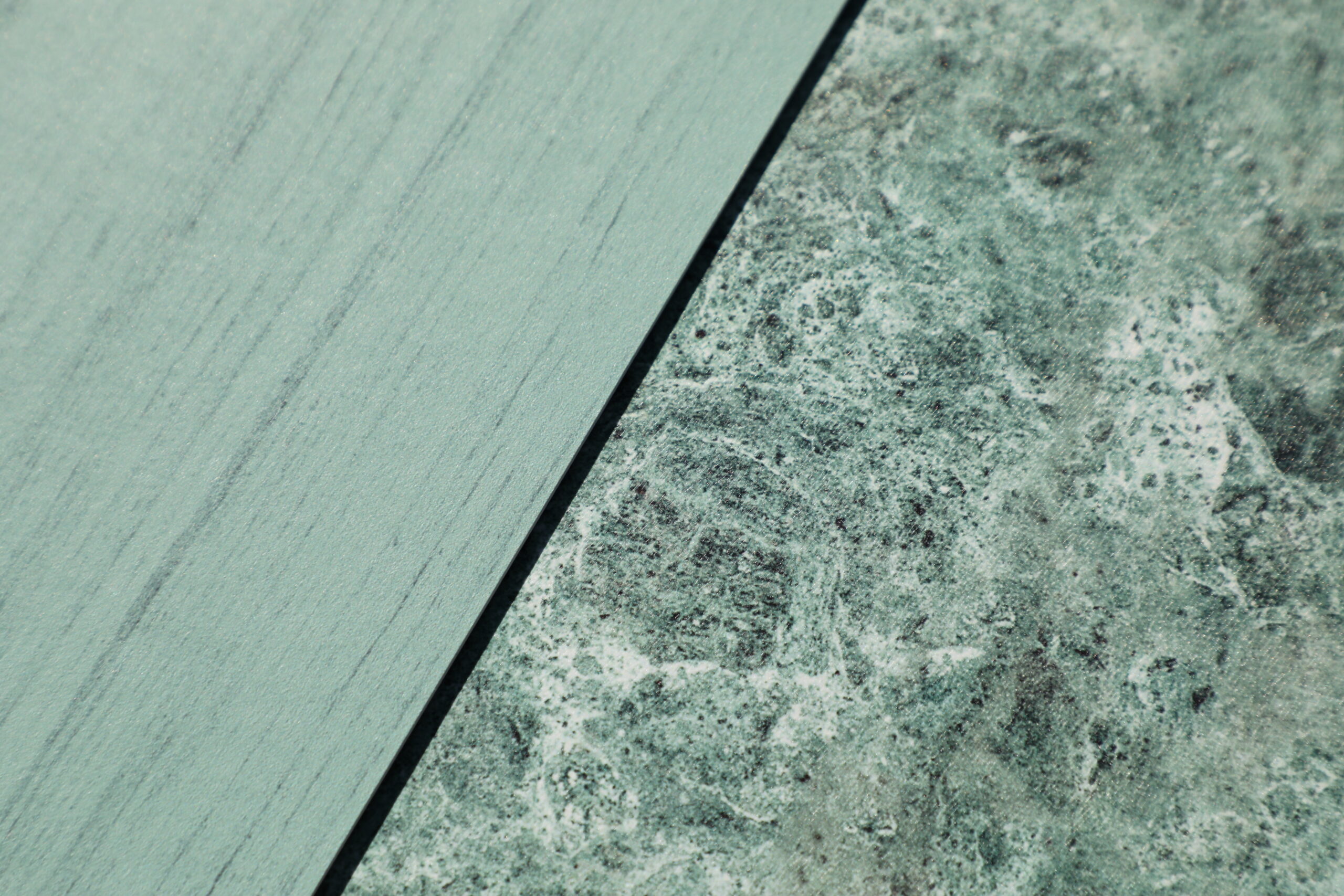

KYDEX ION Technology™

Passenger health and safety are at the forefront of the passenger experience, requiring materials that are chemical resistant, antimicrobial, durable, and stain resistant. KYDEX® Thermoplastics are inherently antimicrobial and available with a range of additional antimicrobial protection options. KYDEX® ION Technology™ products are available with custom colour, pattern, and texture. They are ideal for high touch areas such as tray tables, seat backs, armrests, luggage racks, and bulkhead components.