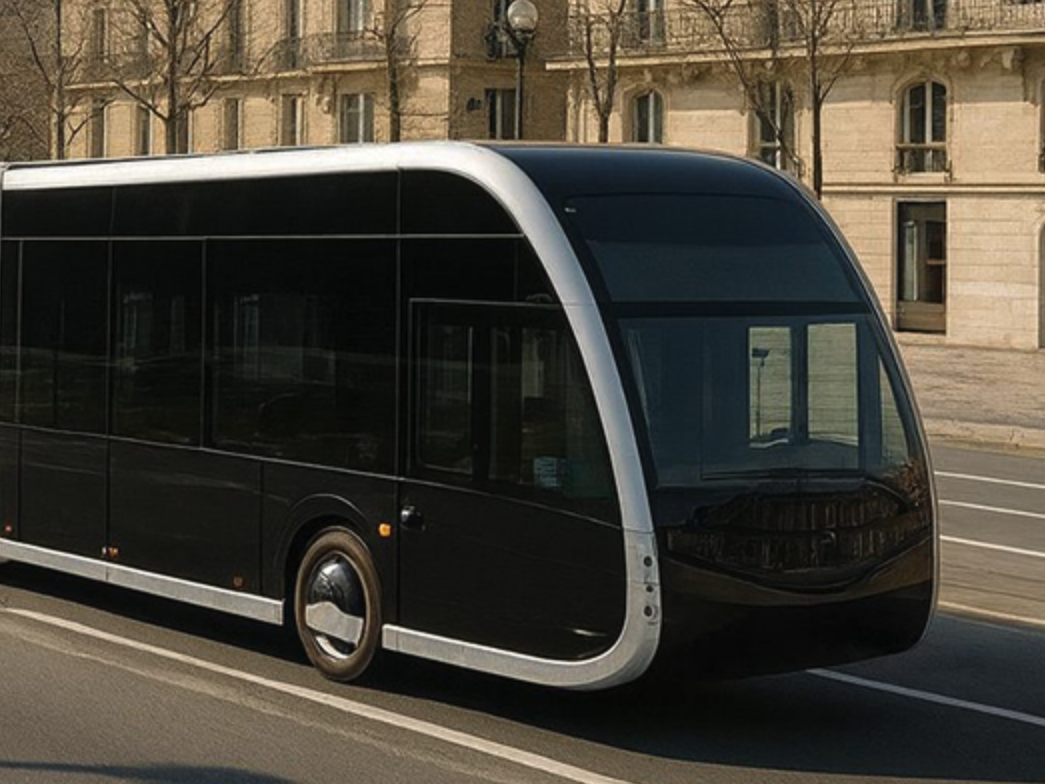

PEI Mobility is leading the way in sustainable mobility with its groundbreaking carbon fibre production technology.

The innovative SMC (Sheet Moulding Compound) technology combines the advantages of carbon fibre, such as lightweight design and strength, with the efficiency of a fast, industrialisable process like press moulding.

Advantages of SMC Technology

SMC technology uses short fibres to create complex-shaped components while keeping costs low and ensuring efficient material use. This automated process guarantees consistent product quality over time, both in shape and performance.

CW695 Carbon Fibre and Steel Articulation

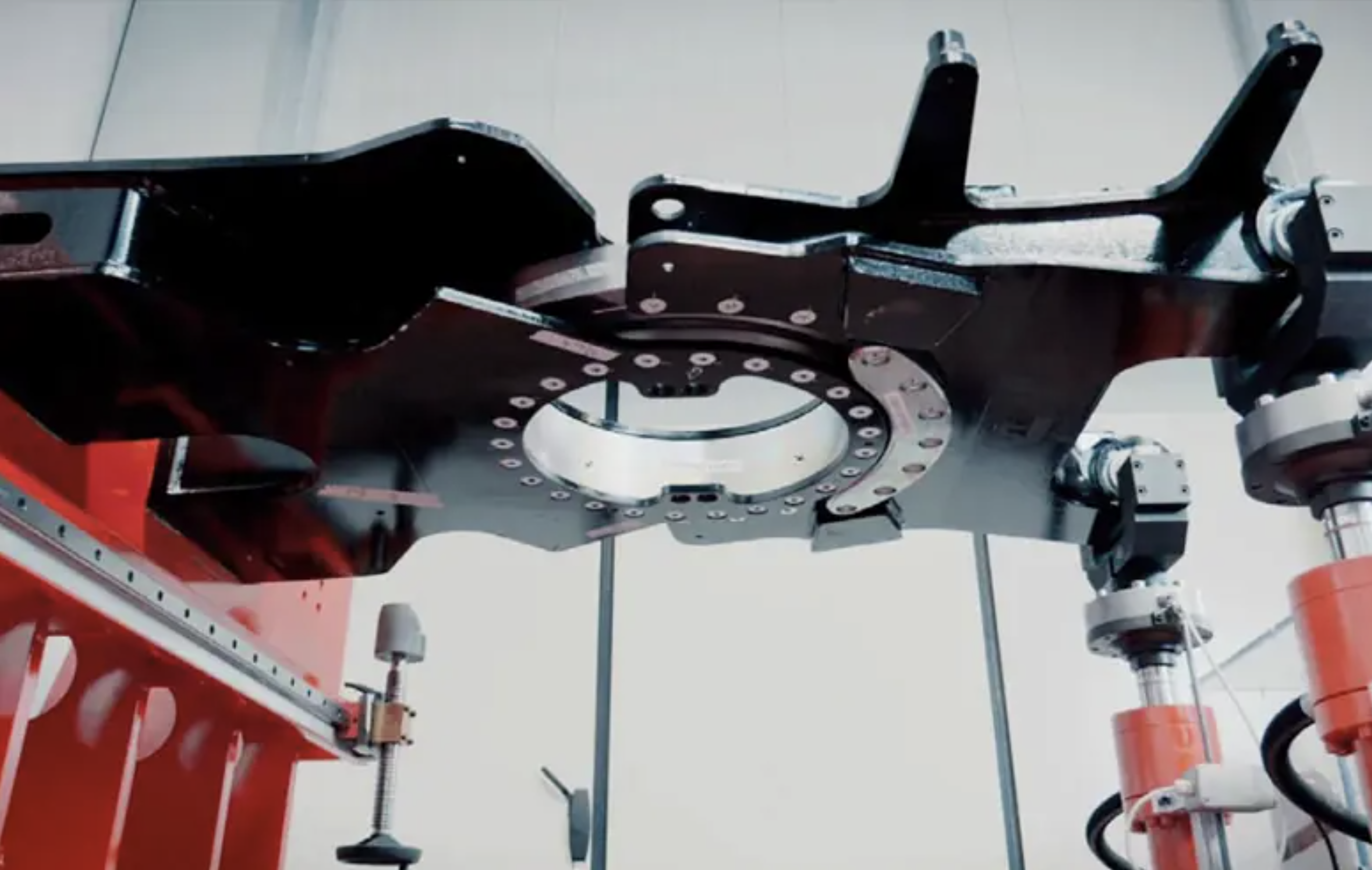

Pei Mobility’s CW695 articulation combines carbon fibre with conventional materials, offering unparalleled lightness and exceptional performance. Key features include:

- Carbon Fibre Structure: Assembled with certified structural adhesive for strength and durability.

- Independent Shock Absorbers: Enhance vehicle stability control.

- Elastic Joints: Provide superior vibration damping for greater passenger comfort.

- Versatility: Suitable for both low- and high-floor buses.

- Durable Fastening Systems: Sliding pads ensure long platform life.

- Low Maintenance: Self-lubricated cylinders reduce maintenance needs.

- Weight Efficiency: 170 kg lighter than equivalent products, enhancing vehicle efficiency.

Benefits of Carbon Fibre Articulation

Integrating carbon fibre in vehicle articulation reduces weight, improves performance, and increases efficiency. This innovation leads to lower energy consumption, greater vehicle range, and reduced environmental impact, aligning with global sustainability goals.

Commitment to Innovation

Pei Mobility’s CW695 carbon fibre and steel articulation sets new standards in sustainable mobility, showcasing the company’s dedication to innovation and a greener future. Explore how Pei Mobility is revolutionizing the mobility sector with its cutting-edge carbon fibre production technology and sustainable solutions.

This article was originally published by PEI Mobility.