In Europe, a large majority of current electric buses are charged with direct current (also called DC).

AC buses are more common outside Europe, particularly in China. Discover all the possible solutions for recharging electric buses with direct current, depending on the different aspects of your vehicle fleet.

What Solutions Are Available for Recharging My Vehicle?

Two Types of Connection Solutions: Per Socket and Per Opportunity

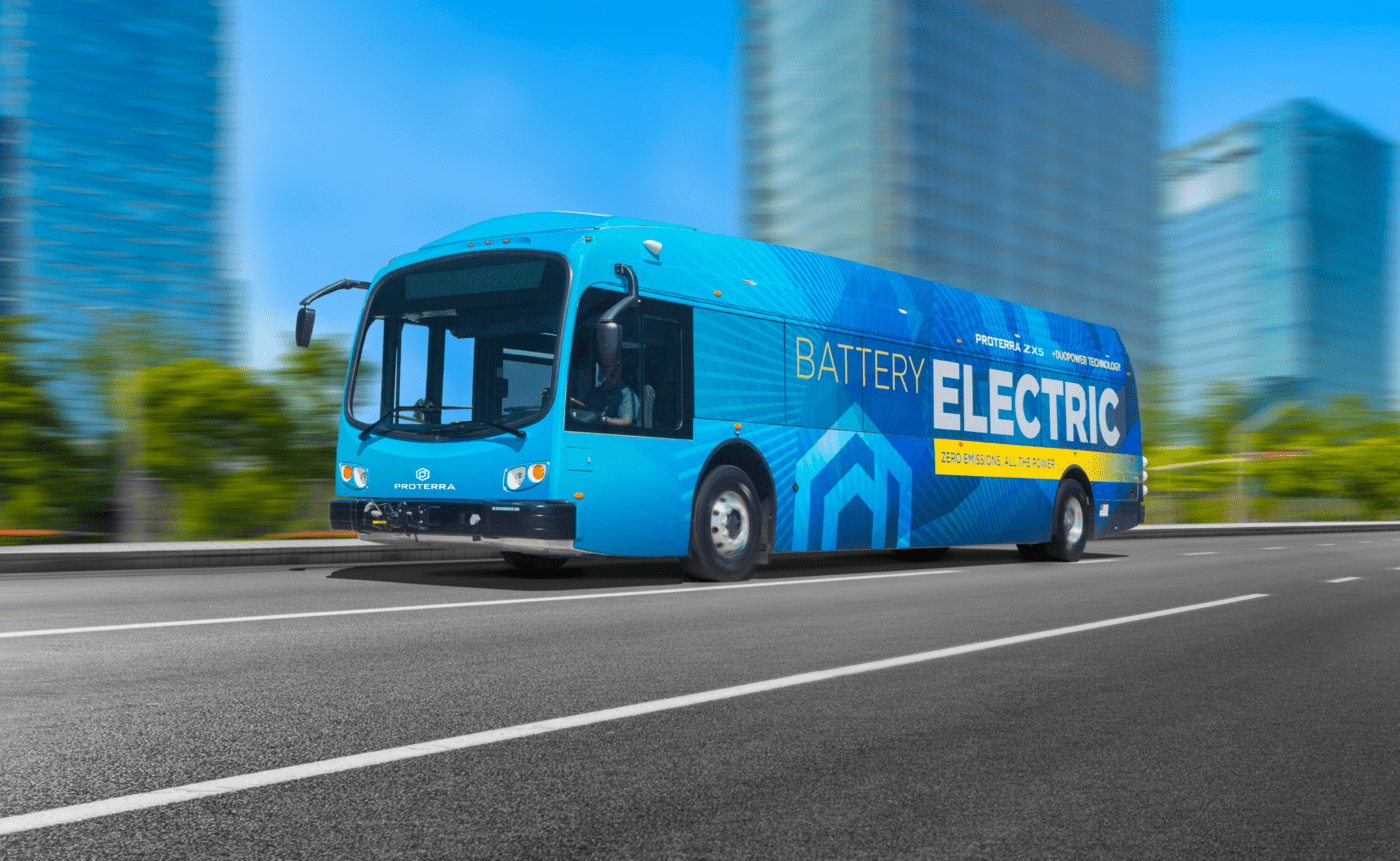

Electric buses with a battery are powered only by the battery on the vehicle, which provides the energy required. The choice of bus and battery size will depend on the power requirements, electrical energy, distance to be covered, climate, topography of the journey and the chosen recharging infrastructure.

There are two connection solutions for vehicle charging:

- Plug-in charging (CCS2 in Europe). This connection method represents the traditional energy supply model for the vehicle ( similar to refuelling). The user manually connects the charging socket to the vehicle. This type of socket is available on our Comeca chargers, for power ratings of 50 to 160 kW.

- Recharging by opportunity (via a pantograph, dome, etc.) allows much greater power to be conveyed and therefore considerably reduces the vehicle’s charging time. No manual intervention is necessary with this technology: it is the vehicle that warns of its arrival and alerts the charger of its intention to charge. Physical contact is then established between the two systems. This technology can deliver power up to 640 kW

3 Possible Recharging Solutions: At the Depot, at the End of the Line and at the Station

Different recharging solutions are possible for 100% battery-electric buses:

- Charging at the depot: the bus is recharged during the inactivity phase (usually at night) in order to be ready for the start of the service (in the morning). The distribution of energy to all the charging stations is then managed globally to smooth out the electrical power over the entire charging period, which is known as “smart charging“. Various elements are taken into account: bus parking times, service schedules, etc. This technology makes it possible to reduce the size of the electricity delivery point and the electrical infrastructure associated with the charging stations. It also reduces the amount of electricity and therefore the total cost of ownership of the buses.

- The end-of-line charging system: this method allows rapid recovery of autonomy and thus limits the size of the batteries. The bus terminus must be connected with sufficient power to limit the down time of the bus to a few minutes.

- The pantograph charging system (ascending or descending): This system requires a stop of a few seconds or minutes (from 3 to 10 minutes) and allows the vehicle with low capacity on-board batteries to increase its range by limiting the size of its battery. The vehicle is therefore recharged at some station to ensure its journey.

These methods are not necessarily exclusive and can be combined to suit the needs of each mobility operator and each city: it is possible to recharge the bus in the evening at the depot and by pantograph during the day, for example. The preferred solution must be selected taking into account the needs and constraints of each player.

Interoperability

Electric Bus and Charger Accounting

Interoperability must allow each vehicle put on the market to be recharged by different brands of chargers. When it comes to charging infrastructure for electric vehicles, standards are evolving and compliance with them may be partial. On-board systems have software versions that are constantly evolving, which is why manufacturers of charging stations have set up an interoperability test programme with manufacturers of buses and electric cars that meet the Combo CCS standard. The manufacturers of electric bus chargers regularly monitor the manufacturers’ market to identify new entrants and plan interoperability tests. At the end of these tests, an “interoperability statement” is generally co-signed with the manufacturer concerned.

The charging infrastructure market has a large number of players. Few are capable of adapting to the constraints for 360°, turnkey projects that will guarantee an appropriate investment cost, a limited cost of ownership, assured availability, flexibility in operation and the evolution of charging power over the life of the installation.

This article was originally published by Comeca Group.